Quality Assurance

We prioritize customer satisfaction and strive to provide environmentally-friendly,

safe products of impeccable quality in order to open the way to a sustainable future.

Quality Management Principles

-

01

Realization of Customer Value

We strive for customer happiness and provide proactive total solutions that prioritize our customers.

-

02

Safety/Environment

We create a safe working environment where all members can work with peace of mind.

-

03

Quality Innovation

We secure a stable level of quality based on differentiated quality management.

-

04

Technological Competitiveness

We achieve overwhelming cost competitiveness and distinctive product competitiveness

through continuous technological innovation.

Quality Management Objectives

Improving Customer-

Centric Satisfaction

-

•Achieving “Zero” customer complaints

•Timely response to customer needs

•Clear identification of root causes and prevention of recurrence

Prioritizing Safety

and Environment

-

• Creating a safe and sustainable environment

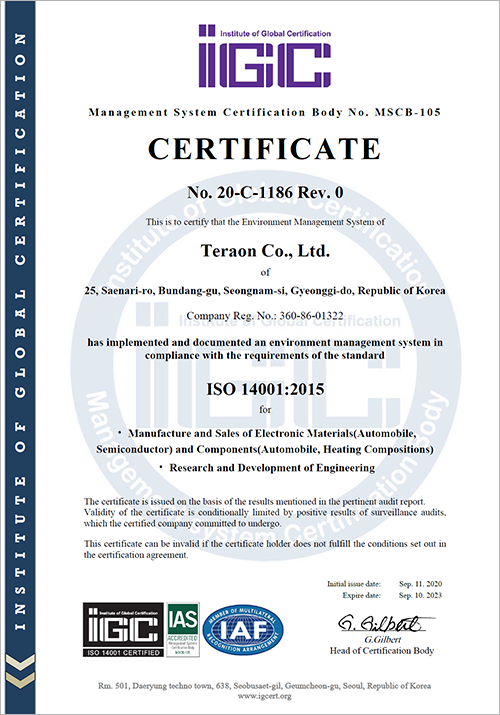

• Certification and management of quality standards based on safety and environmental considerations

• Prevention and proactive response to incidents and accidents

Ultimate Quality

Differentiation

-

• Systematizing quality assurance and implementing strict quality management

• Cultivating a quality-oriented mindset among all members

• Minimizing quality costs and achieving “Zero” defect rate

Seamless Excellence

from Materials to Products

-

• Maintaining top-tier levels of core technology

• Securing overwhelming product competitiveness

• Optimizing manufacturing technology efficiency

Key Functions of Quality Assurance

Strengthening Manufacturing Process and Enhancing Quality Process

- Incoming Materials/

Components - Manufacturing

Process - Product Shipment

- Product Analysis

- Root Cause

Analysis

-

•Inspection and management of

incoming materials/components

•Supplier management

(process-linked analysis)

•Specification management for

materials -

•In-line monitoring

•Management of quality variations

•Management of process change

points

•Calibration of measurement

equipment -

•Shipment inspection

(certificate of analysis, visual

inspection)

•Management of product quality

variations

•Product tracking -

•Physical analysis of defective

products

•Database establishment for

root cause analysis by defect

type -

•Clarification of root causes

•Identification of improvement

points

•Improvement of manufacturing

process

ISO 1400

ISO 9001

IATF 16949

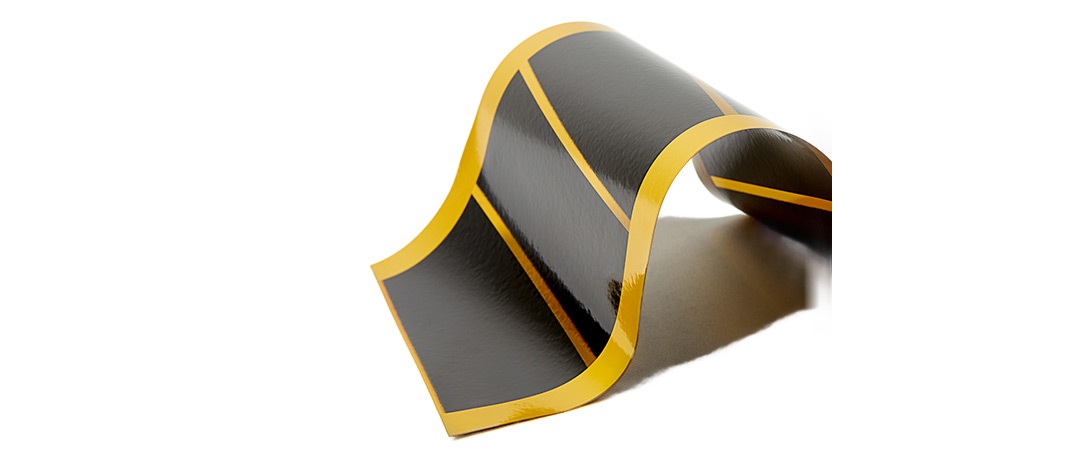

Automated Processes

Teraon implements automated processes to manage production in real-time.

MES & ERP

Through the implementation of MES & ERP, Teraon has implemented an optimal system for real-time

production management and quality analysis in the field of material and heater manufacturing.

User-friendly

-

Provision of materials and products, inventory management, production performance and history monitoring(utilizing wireless PDAs)

Scalability

-

Advanced production/quality management and adaptability to factory/line expansion (factory-wide application/integrated management)

Traceability

-

Product and material production history tracking for improved yield and analysis of internal/external defects(utilizing QR codes)

Integration

-

Provision of necessary information for sales/purchase management and support for financial management and cost control (ERP integration management)

-

Factory 1

-

Factory 2

-

Product Development

Innovative product development based on customer requirements and cutting-edge technologies

- Patents/

Technologies - Product

Specifications - Customer

Specifications - Drawing

Management - Certification/

Sampling

- Patents/

-

Quality Management

Raw Material Inspection ▶ Process Quality ▶ Finished Product Quality Management

- Raw Material

Quality - Process

Quality - Finished

Product

Quality - Non-

conformance

Management - Quality Trend

Analysis

- Raw Material

-

Sales Management

Order and sales planning management, delivery and customer response

- Order

Management - Sales

Planning - Delivery

Management - Shipment

Management - Customer

Interaction

- Order

-

Production/Material Management

Production Planning ▶ Work Instruction Management ▶ Process Management

- Production

Planning - Work

Instruction - Material

Ordering - Material

Inventory

Management - Process

Management

- Production